Categories

Environmental Policy Statement

Quanex Building Products Corporation (“Quanex” or the “Company”) is committed in all respects to acting in an environmentally responsible manner and playing its part contributing to a more sustainable world through its people, operations and products. The Company is committed to sustainability excellence and continual improvement in its environmental performance through the goals set out in its sustainability roadmap and reporting its progress externally on an annual basis.

Our sustainability program is overseen by our Board of Directors and Sustainability Leadership Council. The VP Operations Excellence has overall accountability to the CEO on the Company’s environmental performance with support from the VP Global EHS for ensuring compliance with local environmental laws/regulations and a VP Global Sustainability for keeping this policy up to date and providing direction on its sustainability strategy. Each division President is responsible for the environmental performance within their business, including providing effective leadership, allocating requisite resources and ensuring the requirements of this policy are met, along with the achievement of companywide goals and maintenance of effective environmental management systems.

Achieving excellence in our environmental performance is a collective responsibility and leaders at all levels are expected to engage their teams to identify opportunities for improvement and recognize good practices. Every Quanex employee is responsible for following the Company’s environmental procedures and reporting any environmental incidents to their line manager/supervisor. All Quanex businesses commit to:

- Applying best available techniques to prevent pollution, protect the natural world, promote circularity and comply with all environmental laws, regulations, permits and other standards applicable to their products and operations

- Allocating sufficient resources to ensure the effective implementation of this policy

- Procuring raw materials, components and packaging from responsible and sustainable sources, as well as working with their supply chain partners to minimise their impacts across the value chain

- Consulting stakeholders on environmental issues to identify priorities for action

- Embedding sustainability and lifecycle thinking into product development processes to create new products and services with improved environmental performance in their manufacture and/or in use

- Providing information on the environmental impacts of products and collaborate with their customers to help them meet their sustainability requirements and goals

- Addressing the carbon footprint of their operations by optimizing their use of energy through energy efficiency actions, sourcing renewable electricity and deploying renewable energy technologies

- Minimising their impact on water resources by implementing water efficient practices, prioritising areas of highest use and/or regions with high risk of water scarcity

- Reusing, recovering and/or recycling hazardous and non-hazardous wastes in their production processes

- Raising environmental awareness among their workforce through information, training and education to encourage their contribution to a more sustainable future

- Identifying and managing the environmental risks and opportunities associated with all major business decisions, including due diligence during acquisitions and divestments

- Maintaining data collection systems to track the environmental performance of products and operations to enable the Company to report its progress publicly.

Environmental Stewardship and Minimizing Our Footprint

We strive to manage our business in a way that minimizes our environmental footprint, and we employ a Quanex-wide Vice President of Global Sustainability to help guide our efforts in this regard.

Our PVC extrusion business recycles almost all of its own scrap vinyl and has repurchased and recycled scrap from its customers for many years. Recently, our cabinets business has partnered with several third parties to recycle or repurpose much of the sawdust and wood chip waste that results from our manufacturing process, often as animal bedding. Waste sawdust is also used as a renewable energy biofuel to fire our drying kilns. Throughout the business, we look for similar opportunities to avoid contributing waste to already-overburdened landfills and waste disposal sites, and we utilize continuous improvement and six-sigma techniques to help improve quality and reduce waste both at our own facilities and those of our customers and suppliers.

We believe that access to safe water and sanitation is a fundamental human right. As such, we take steps to reduce our water usage and waste outflows to minimize the impact of our operations on any water sources or freshwater ecosystems that may be near our facilities, and we expect the same of our suppliers.

Another important avenue to protect our environment is the reduction or elimination of waste, especially hazardous waste. Our locations are committed to continuous improvement in reducing waste through recycling programs, improved manufacturing processes and using waste products as alternative fuels.

Quanex’s current sustainability goals are detailed below. These goals are under review following the Company’s purchase of the Tyman business in 2024 and will be updated with the release of a new 10-year sustainability strategy for the combined business, expected for release later in 2025.

By 2034

-

15% Reduction:

Non-Renewable Electricity

-

10% Reduction:

Non-Hazardous Waste

-

35% Reduction:

Carbon Fuels Usage

-

10% Reduction:

Hazardous Waste

-

20% Reduction:

Natural Gas Usage

-

20% Reduction:

Water Usage

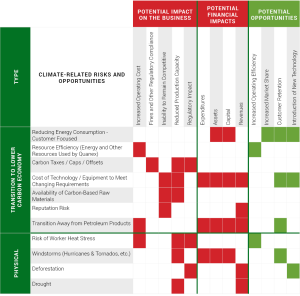

Quanex is keenly aware of the financial and operational risks that climate change poses to the overall business and to the world at large. However, we also believe that climate change presents several opportunities for business expansion, reduction of financial risks and improvement in the Company’s overall sustainability.

Below is a list of climate-related metrics that we measure on a companywide basis as part of our long-term plan to reduce our climate impact.

- Total energy usage

- Renewable energy usage

- Production scrap, overall waste, and associated recycling efforts

- Scope 1 and scope 2 greenhouse gas emissions

We have not yet developed specific improvement goals for each of these metrics because we believe that any specific goals will be meaningless unless we have first refined our ability to document these metrics accurately and consistently across all our plants and ensured that we have fully integrated the Tyman business into Quanex. Once the integration is complete and these new measurement systems are fully implemented and working appropriately, we will then work to set baselines and begin developing specific improvement goals and implementation plans for those areas where we can make a true impact. While our specific planning process is in its early stages, we understand the effects of climate change and we are beginning to analyze various ways to minimize our carbon footprint and other environmental impacts for the good of all our stakeholders.

While we work to build these new measurement systems and plans for future improvements, our current operational focus is primarily on the reduction of scrap and machine downtime. Improvement in those areas will allow us to reduce our energy consumption while simultaneously providing value and reducing risk for our stakeholders. This reduction in energy consumption will in turn reduce our carbon footprint and overall climate impact.

Findings of the initial assessment of climate-related risks and opportunities for Quanex are reported below. Comprehensive disclosures of climate risks were also made by the legacy Tyman business for fiscal 2023 and can be found here. We anticipate being able to report further progress in harmonizing our approach to climate-related risks and opportunities for the combined business in fiscal 2026.

Climate risks to the business

Working with leaders of the various divisions of Quanex, we have identified certain climate risks that are pertinent to each of our divisions.

North American Fenestration (NAF)

Some of the raw materials and chemicals used in our PVC extrusions and insulating glass spacers are manufactured at plants located along the U.S. Gulf Coast. These plants have weathered several strong hurricanes over the past few years, and it appears that climate change is resulting in storms that are both more intense and more frequent. We have seen similarly troubling weather patterns in areas where our own plants are located, including the 2021 polar vortex that reached deep into southern United States and the frequent wildfires that seem to threaten California on a yearly basis. As climate change continues to drive more extreme weather, these events will presumably become more common and will increase the risk to our plants and our supply chain.

Quanex Custom Components (QCC):

Our cabinet components business maintains a location in Oregon that is also subject to increased wildfire risk in the future as climate change continues to drive extreme drought on the West Coast.

European Fenestration:

As with NAF, the European Fenestration business relies heavily on a supply chain that includes raw materials and chemicals manufactured along the US Gulf Coast. Disruptions to that supply chain that result from increasingly severe storms could lead to higher prices or even complete unavailability of certain materials. In addition, Europe and the United Kingdom also continue to see an increase in the severity and frequency of extreme weather events that can threaten our facilities or those of our customers and suppliers. Western Germany, for example, recently experienced an unprecedented flooding event that caused the temporary shutdown of our Heinsberg plant.

Internal Audit Program

Under the leadership of our VP Global EHS and our internal legal team, and with the participation of auditors from many levels of the organization, we maintain a robust internal audit program. We conduct multiple on-site audits every year, with audit locations determined annually by the VP of Global EHS in conjunction with the legal team. We use standardized audit protocols that ensure our facilities meet a consistent set of standards regardless of their location. Upon completion of each audit, any required corrective actions are developed in conjunction with the plant’s leadership team. We then utilize our online task alert system to ensure that all corrective actions are completed in a timely manner. Finally, our VP Global EHS verifies completion of all tasks within the prescribed time period.

Product Leadership

We strive to develop products that have positive environmental impacts in use and in terms of how they are formulated. Across our businesses, we develop products that are specifically designed to improve energy efficiency in buildings. Many of our vinyl extrusions and insulating glass spacer products, for example, exhibit world-class performance in energy efficiency and are used around the world in LEED-certified and other energy-efficient buildings.

Our dedication to sustaining the environment is evident at all levels of our business, and we will continue to strengthen those efforts in the future. Around the world, we will work to seize available opportunities to reduce our environmental impact and to continue our development of products and technologies that are energy-efficient and with lower environmental impacts.

Information on this page was last updated: 05/20/2024